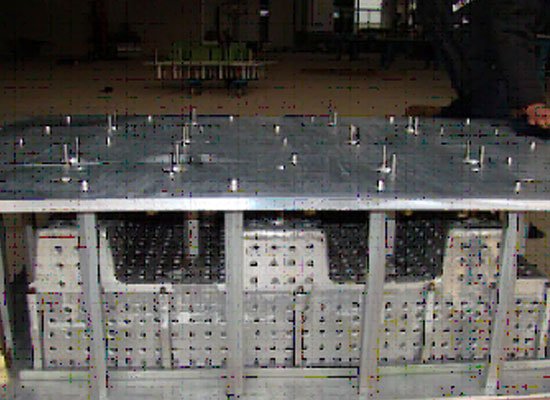

CAVITY PORTION OF A MOULD

January 31, 2024

BOX MOULD IN CHINESE MODE (PART2)

January 31, 2024TILE BOX EPS MOULD IN CHINESE MODE(PART1)

₹450,000.00

Aloukik Thermotech Industries, proudly presents our tile box eps moulds, representing the pinnacle of Chinese manufacturing excellence. Featuring meticulous craftsmanship and cutting edge EPS mould technology, our moulds are crafted with precision to produce high-quality tiles Mould boxes with innovative EPS designs. Engineered to handle intricate shapes and details, they facilitate the effortless production of complex and versatile EPS mould products. As a trusted EPS mould supplier, we prioritize quality and performance, ensuring our moulds endure the demands of manufacturing. Experience the difference with Aloukik Thermotech Industries as we set new standards in moulding technology. Our tile Mould Boxes, inspired by traditional Chinese “water drawer” designs, are ideal for plumbing, flooring, and various DIY projects. Designed to meet the demands of tiles packaging, offering durability, easy installation and use, these boxes come in a range of sizes and styles. Constructed from high-quality materials such as steel, aluminum, and plastic, they offer durability and long-lasting performance. Aloukik Thermotech tile box EPS Moulds are a preferred choice among homeowners, contractors, and building professionals for tiles packaging solutions. Experience the difference with Aloukik Thermotech Industries as we set new standards in moulding technology, especially in EPS mould for tiles packaging. Trust Aloukik Thermotech Industries for exceptional tile box EPS Moulds solutions that combine traditional design with modern manufacturing prowess.

We follow below steps to make Durable EPS Moulds

- Design top-quality EPS moulds from provided drawings, samples, or shapes.

- Create prototype samples with Vertical Machining Centers (VMC) for evaluation.

- Use VMC for pattern work to ensure consistent wall thickness, boosting EPS production efficiency.4.

- Maintain proper spacing for steam vents to reduce production time.

- Install suitable cooling lines using stainless steel (SS), copper, and galvanized iron (GI) with sprinklers.6.

- Face chamber frames for precise alignment.

- Build sturdy chambers using heavy MS strips, secured with stainless steel bolts for durability.

- Use high-quality aluminum alloy for the mould frame.

- Process with CNC machines for precise sizing.

- Apply Teflon coating.

Reviews

There are no reviews yet.