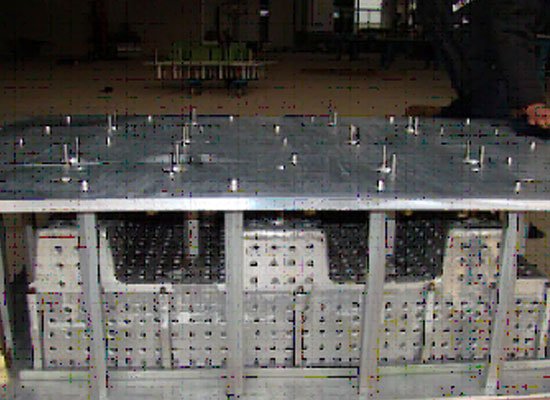

PUNCH PORTION OF INDIAN MOULD

January 31, 2024Discover the innovative EPS mould designs of our cavity portion of Indian Mould, revolutionizing the moulding process. Crafted with precision and expertise by AloukikThermotech Industries, your reliable EPS mould supplier, our cavity portion incorporates cutting-edge EPS Mould technology to redefine mould functionality. Engineered to accommodate intricate shapes and details, it facilitates the production of complex and versatile EPS Mould products with ease. Made from high-quality materials, it ensures durability and longevity, even under demanding manufacturing conditions. With superior accuracy and consistency, our innovative EPS mould designs set new standards in moulding excellence, offering unmatched performance and reliability for your production needs.

We follow below steps to make Durable EPSMoulds

- Design High-quality EPS moulds based on provided drawings, samples, or component shapes.

- Create prototype samples using Vertical Machining Centers (VMC) for evaluation.

- Utilize VMC for all pattern work to ensure consistent wall thickness, improving EPS production efficiency.

- Maintain proper distances to incorporate steam vents, reducing production time.

- Integrate suitable cooling lines in chambers using materials like stainless steel (SS), copper, and galvanized iron (GI), along with sprinklers.

- Perform facing of chamber frames to ensure precise alignment.

- Construct sturdy chambers using heavy MS strips and secure them with stainless steel bolts for long-lasting durability.

Reviews

There are no reviews yet.